Product Description

Introduction:

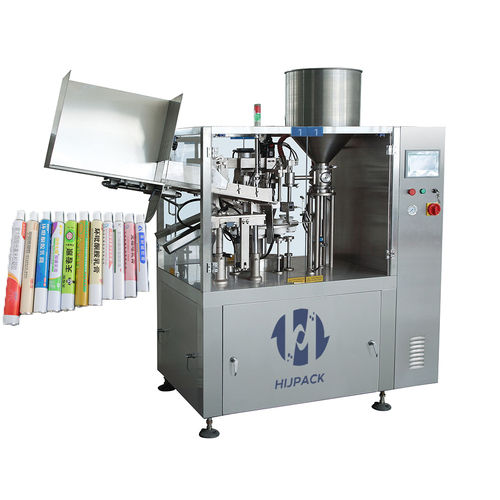

NF-60A Automatic tube filling & sealing machine adopts import foreign advanced technique,specially designed according to technology of cosmetics, ointment cream products,machine include automatic tube feeding,heating,sealing,pretreatment system,filling adopt mechanical piston, electrical control system and operation platform system.

Feature:

- No tube no filling.

- Have counting function and point function when reach set amount.

- Error alarm,stopping and alarm in case of door opening,stopping and alarm for too low main air pressure,alarm function for overloading,Emergency stop.

- Automatic print batch number,Automatic tube discharging.

- Automatic tube feeding, automatic benchmarking.

- Automatic filling,tail cutting function for viscous material.

- Main drive system located at the bottom of the machine table,safe and no pollution.

- Filling and sealing part are installed in a semi-closed and no static electricitys transparent cap,and installed in the platformeasy to observation and operation.

- Smooth and flat surface, free of dead corner, being innoxiously and non-smell, free of pollution, easy cleaning, and easy maintenance and servicing.

- Compact structure, simple and convenient operation, the machine is applicable to many industries such as medicine, food and daily chemical industry etc.

HIJ-TF60A AUTO TUBE FILLING AND SEALING MACHINE | |

| Configuration Standard | Technical Parameters | Remarks | |

Infrastructure | |

| Main Machine Landing Area | (about) 2m2 | | |

| Working Area | about12 | | |

| Water Chiller Landing Area | about1 | | |

| Working Area | about2 | | |

| Whole Machine (LWH) | 195010001800mm | | |

| Integrated Structure | Union mode | | |

| Weight | about850Kg | | |

n Machine case body | |

| Case Body Material | 304 | | |

| Opening Mode of Safety Guard | Handle Door | | |

| Safety Guard Material | Organic Glass | | |

| Frame Below Platform | Stainless Steel | | |

| Case Body Shape | Square-shape | | |

n Power, Main Motor etc. | |

| Power Supply | 50Hz/380V 3P | | |

| Main Motor | 1.1KW | | |

| Hot Air Generator | 3KW | | |

| Water Chiller | 1.9KW | | |

| Jacket barrel heating power | 2 KW | Optional additional price | |

| Jacket barrel blending power | 0.18 KW | Optional additional price | |

n Production Capacity | |

| Operation Speed | 30-50/min/max | | |

| Filling Range | 5-250ml | | |

| Suitable Tube Length | 50-210mm | Pipe length more than 210mm should customize | |

| Suitable Tube Diameter | 13-50mm | | |

n Pressing Device | |

| Pressing Guiding Main Component | CHINA | | |

n Pneumatic Control System | |

| Low Voltage Protection | CHINA | | |

| Pneumatic Component | AIRTAC | | |

| Working Pressure | 0.5-0.7MPa | | |

| Compressed Air Consumption | 1.1m/min | | |

n Electrical Control System | |

| Control Mode | PLCTouch Screen | | |

| PLC | TAIDA | | |

| Frequency inverter | TAIDA | | |

| Touch Screen | WENVIEW | | |

| Coder | OMRON | | |

| Filling detect Photo electric cell | AUTONICS | | |

| Total Power Switch etc. | CHINA | | |

| Color Code Sensor | JAPAN | | |

| Hot Air Generator | LEISTER (Switzerland) | | |

n Suitable Packing Material & Other Devices |

Suitable Packing Material | Aluminum-plastic composite tube and Plastic composite tube | |

Obliquely Hanging Lining-up Tube Storehouse | Speed Adjustable | |

Material contacting with filling material | 316L Stainless Steel | |

Jacket layer hopper device | Temp. Setting according to material and filling demand | Optional additional price |

Jacket layer stirring device | In case of no material mixing, it remains fixed in hopper | Optional additional price |

Auto stamping device | Single side or double sides printing at the end of seal tube. | Single side or double sides additional cost |

|

|

|

|

|

|

|

|

Due to the continuous improvement of the equipment, if part of the electrical changes without notice.